When everyone dreamed of cable television, we wired Germany. When telephoning became mobile, we brought the signals to the antennas. Now everyday life is going digital and we are transferring large amounts of data in data centers around the world.

New technologies are constantly changing the world of data communication. Growing bandwidths and speeds are continually creating new transmission standards for the communication networks of tomorrow. With a lot of innovation, we develop safe and powerful cable systems for new technologies. We deliver standardised or customerised solutions for data centers, mobile communications and space travel.

Our Quality Management

Cosistent high quality output worldwide

The outstanding quality and reliability of our products and system solutions make our name a brand. With these properties we set standards in the market worldwide.

In addition to the continuous improvement of our product and process quality, rapid reaction to customer and market requirements is an important cornerstone of our quality policy. The entire process from planning to completion of a product is subject to permanent monitoring and continuous documentation at all our locations. Our quality management systems are certified according to DIN ISO 9001 and occasionally according to DIN EN 9100.

Our Environment & Energy Management

Sustainable for the world of tomorrow

Digitalisation, globalisation and urbanisation are changing the world. It has become smaller, faster and more complex. We meet the challenges of change with visionary thinking and forward-looking action in order to shape the future with intelligent and innovative products that conserve resources and are sustainable.

Our Technologies

... in cable production

The structure, shielding and materials used are of crucial importance for the mechanical and electrical properties of a cable. Our extensive fleet of machines in our worldwide production facilities enable the production of a broad range of production processes for finishing cables.

As well as…

- the extrusion / wire drawing of all thermoplastic extrudable plastics and special materials developed in our own materials research facility,

- stranding with a defined pitch and position of the wires,

- wire spinning with spiral-shaped wires and wires installed in parallel,

- and braiding to achieve precisely defined coverage, …

…we also offer special shielding foaming and wrapping technologies:

- Extremely stable and uniformly structured dielectrics of our wires in the skin-foam-skin extrusion to optimise the transmission properties of our cables with very narrow diameters.

- Special shielding technologies with different shielding foils ensure low crosstalk and a high signal integrity in high-frequency transmissions

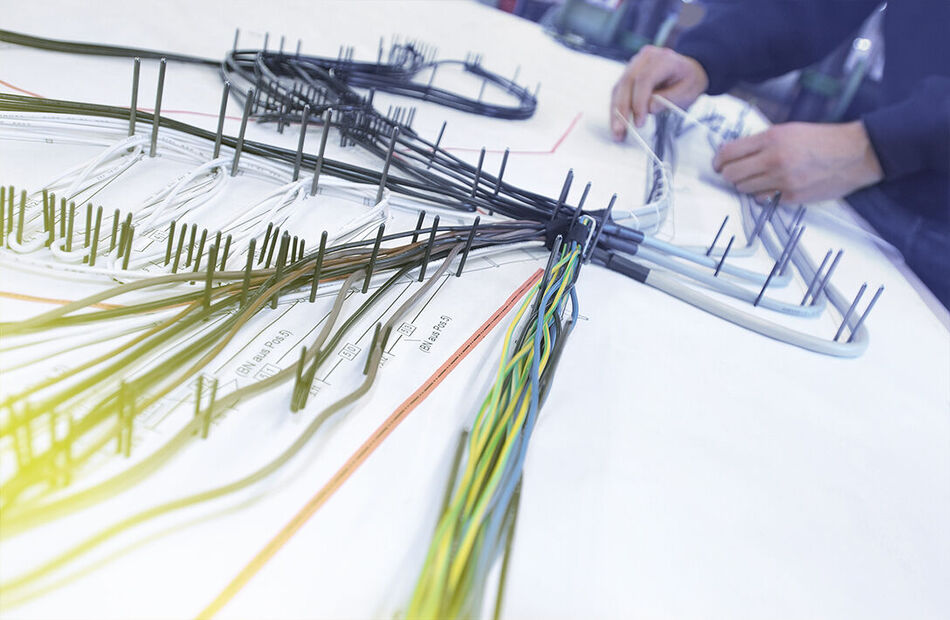

... in cable assembly

We use our own, specially developed optimized machines to connect the PCBs and cables in our high speed cable systems. The automated process is being constantly developed to improve the signal integrity of our NEXT generation products. Our extensive know-how, our employees' qualifications and the state-of-the-art equipment installed in our production facilities worldwide enable us to offer different joining techniques for the secure assembly of our cables:

- Cutting to length incl. stripping, as well as in-phase length and laser stripping

- Crimping

- Soldering, also induction, stamp and hot bar soldering

- Insulation displacement

- Ultrasonic welding

- Casting using hotmelt technology

- Extrusion using injection moulding technology

- Assembly of optical silica fibers, glass fibers, plastic fibers, plastic-coated fibers and fiber bundles

- Assembly of high-voltage cables

Our Research & Development

BizLink R&D labs - Our investment in the future

The improvement of transmission properties, energy efficiency, service life, safety and manufacturing processes is a permanent subject of our research & development.

In our laboratories, employees research high-performance solutions and optimized production processes, as well as the maximum reduction of electrical or mechanical interference through product design and material mixtures.

Performance lab: Optimized manufacturing processes

The continuous further development of existing manufacturing processes increases the performance of our connections and the efficiency of our production. Our unique skin-foam-skin technology for homogeneous wire dielectrics or our innovative pair shielding techniques for maximum signal integrity are exemplary results of this research work.

How we manufacture

Quality lab: Sustainable safety

In addition to application-optimized transmission properties, maximum service life in dynamic and rigid applications with resistance to interference, operating temperatures or media, as well as simple installation and adequate fire behavior are fundamental requirements for the safety of our products. Our high-performance direct attach cables (DAC) with secure transmission of up to 800 Gbit/s or our UL-listed data cables are exemplary results of this research work.

How we ensure quality

Material lab: Material development

The optimum material mixture has a direct influence on the safety of our products in the application environment. Our material lab is constantly developing new material mixtures in order to achieve efficient use of interswitch connections or weather-resistant mobile radio cables, for example.

Next date

No scheduled dates at this time.